Proven RTLS Technology For Mining Industry

This award-winning IoT-RFID solution, which forms the monitoring and decision support management for underground and surface mining operations, is specifically designed for the mining industry. Its objectives include increasing efficiency and productivity, ensuring safer and more effective mining operations, adhering to OHS regulations to avoid potential workplace accidents, developing new management systems based on big data and reporting systems, and ultimately improving competitiveness."

Boost your mining operations with RTLS

Wipelot’s tailored RTLS solutions offer a comprehensive solution to make mining operations smarter and more efficient. The system combines data analysis, automation, and IoT technologies to optimize the mining processes.

Mining RTLS Modules

Personnel Safety

This module ensures precise tracking and safety of personnel in both underground and surface mining operations. It instantly detects situations such as falls or immobility and conducts an automatic headcount of personnel in emergency muster areas. It operates independently and offers adjustable location precision according to needs. Furthermore, it complies with mining occupational health and safety regulations. Additionally, the module enhances personnel safety by integrating with a social distancing tracking system.

For More Information, Click Here

Equipment Tracking

It provides real-time tracking of both motorized and non-motorized vehicles and equipment in underground and surface mines. Additionally, it tracks the working hours of machinery, offers historical route information, and reports on speed violations and driver habits. To ensure a safe working environment, it controls vehicle speed and detects vehicle direction. It monitors engine status, calculates the distance covered, and assists in maintenance and fuel management. Furthermore, it supports more efficient and secure operations by automatically mapping vehicle-operator pairings and authorizations.

For More Information, Click Here

Traffic Management & Collision Warning

Traffic optimization contributes to reduced fuel costs and increased ore extraction. With its expandable structure, it creates signalization network that span kilometers, allowing for centralized monitoring and management. In case of special vehicles like ambulances entering the area or exceeding the vehicle capacity within the mine, it provides automatic signaling guidance. Additionally, it supports scenarios such as entry and exit from levels and main gallery waiting, and offers an adjustable safety zone to prevent collisions around vehicles and equipment. Its closed-circuit operation ensures immunity from general system failures."

For More Information, Click Here

Task Management - ASSOS

ASSOS simplifies task assignment and management for both personnel and vehicles. It provides remote access to the field from a single point, allowing tasks to be accepted or rejected instantly. Information specific to the type of vehicle can be input, and real-time information about which operator is using the vehicle is available. Moreover, it is resilient to challenging working conditions and enhances operational traceability, enabling you to measure efficiency.

For More Information, Click Here

Environmental Parameters & Meter Readings

This module measures, records, and evaluates environmental parameter values in mines in real-time, creating alarms when parametric values are exceeded. It operates on a closed circuit via the Wipelot sensor network, independent of GSM networks or other networks. It can be integrated with existing sensors used in mines, helping to optimize energy efficiency. It measures ambient conditions such as temperature, humidity, light, CO2, and similar factors. It is compatible with extensometers, and alarms can be sent to authorities via email and SMS.

For More Information, Click Here

Analytics and Optimization

This module is an artificial intelligence solution that optimizes task and work durations by analyzing the system's historical task and location data. It ensures the allocation of the right number of personnel and equipment for a specific task and evaluates equipment and personnel performance. It identifies the most efficient personnel and assigns tasks to appropriate individuals based on their competencies and past work history. It reduces travel times, movement durations, and quantities for equipment through route optimization. Additionally, it enables automatic data entry.

For More Information, Click Here

Weighing Automation

It allows for the measurement and tracking of transportation operations between underground and surface facilities without the use of an operator. It reduces operational costs, integrates with real-time location tracking systems, provides data to production and entitlement management systems, allows for instant operation management, saves labor and time with process automation, and performs automatic vehicle-operator mapping and authorization.

Cost reduction due to traffic improvement

10%

Increase in operational efficiency

Decrease in workplace accidents

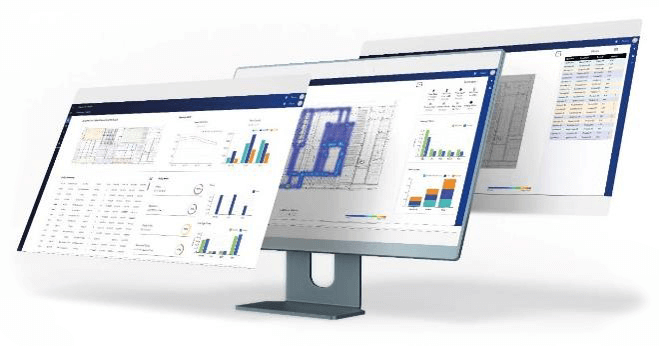

Sustainable Efficiency with Data Analysis and Detailed Reporting

Wipelot's real-time location tracking software, Lotus, and the flow analysis and optimization module, Flow Analytics, elevate asset visibility and provide detailed insights into operational processes in facilities. This enables performance measurement for efficiency and helps mitigate potential risks in occupational safety.

Testimonials

We collaborated with Wipelot to improve the performance of our 112 forklifts in our operations at Vestel City. We were able to identify and minimize forklift productivity losses with Wipelot's own technology.

Wipelot's Safezone Forklift Tracking and Collision Warning System and Lone Worker Safety System applications have contributed to making our production facility safer for all staff and visitors.

At Borusan Port, we worked with Wipelot to improve work safety and reduce the need for labour. We have achieved very effective results in performance and safety by reducing the loss of labour due to filiation by up to 70%.

We chose the Wipelot solution as a platform. With the help of Wipelot, ESAN has achieved significant productivity in OSH strategies and processes

With Wipelot Iot, we increased the efficiency of equipment and vehicles in our facility.

Discover Related Blogs

What is RTLS: Real Time Locating Systems?

Real Time Location Systems, also referred to as RTLS, allow for modern technology to determine the location of an item or person in real time. RTLS doesn’t necessarily have to refer to one piece of technology, but is rather an initiative that can be accomplished through the integration of various systems. It is commonly used for tracking and managing assets in industrial settings. The data collected by RTLS systems can be utilized for many different purposes such as creating timestamps for when an asset moves into a certain area. Another application could be about granular visibility that requires constant updates. RTLS solutions generally capitalize on locating, tracking and managing assets, people and inventories so that companies are better equipped to make educated decisions on the data they have collected and optimize their operations while enhancing workplace safety.

Importance of Traffic Management & Signalization in Mining

Wipelot Signalization System has an expandable infrastructure. An increasing number of vehicles or tunnels. The system can be easily expanded to kilometres and hundreds of vehicles without loss of performance if the number of vehicles or tunnels increases. In addition, thanks to the closed-circle operation feature, it is not affected by general system failures and interruptions.

Discover Related Success Stories

RTLS-Based Task Management Optimization in Mining

RTLS-based task management optimization offers a powerful solution to enhance efficiency and traceability in mining facilities. It enables real-time tracking of equipment, optimization of logistics processes, and increased productivity in production processes. By enabling better planning, resource management, and error analysis, it can reduce operational costs and provide a competitive advantage in mining operations.